Two posts ago, we focused on the birthplace of cannabis (the manufacturer/grower) along with some of the limitations easily observable in their current system. If you’d like to get up to speed with us, first check out the post below for the full story. Let’s now talk about the next player in our cast of characters – the distributors.

In most states, distributors come in the form of medical dispensaries. Along with the growth of this industry, comes the demand for legitimization. This means consumers are demanding proof of a high quality, and more importantly, contaminant-free product. “What are dispensaries testing for?” you ask. Great question. The answer is pretty straightforward:

- The percent concentration of cannabinoids (mainly THC/CBD/CBN)

- The percent concentration of major terpenes (e.g. Myrcene, Limonene)

- The presence of harmful chemicals/pesticides/mold in the batch (not all dispensaries test for this)

Testing for cannabis can be done in two ways, here is a quick graph explaining each process and some of the differences:

Demand for these types of testing is understandable yet standardized testing of each product isn’t as easy as you might think. There are list of challenges faced by distributors testing for quality.

One challenge is that a long chain of custody is required and samples must be picked up or dropped off in person at a central testing facility with complex paperwork. Additionally, dispensaries carry a host of strains and testing all of them can cost anywhere between $60-$300 per sample (that will add up quickly). Furthermore, their testing requires 1 to 4 grams of each strain to yield results, (product that dispensaries would rather be selling). However, the biggest flaw in the current system is lack of easy access to central testing labs.

Long story short, it costs dispensaries a decent chunk of time, money, and product to perform these tests; and worst of all, testing is not easily accessible. Central lab testing is necessary for any dispensaries looking to provide high-quality medicine. Unfortunately, doing so does not alleviate all of the dispensary’s problems.

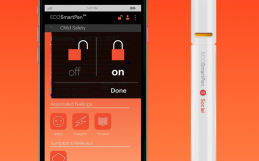

Much like aging has an effect on a bottle of wine, the concentration of compounds in a particular cannabis sample changes over time. It would be extremely expensive and time consuming for dispensaries to repeatedly send out samples to central testing labs. MyDx is the perfect solution to this problem. The power of our device will allow dispensaries to verify central testing lab measurements and monitor the percent changes of compounds in a strain from the time it is checked into inventory to the point of sale.

So, what do you think? How else could dispensaries use MyDx to ensure premium product? Would you rather go to a dispensary that tested with MyDx? Do you think those dispensaries would get more business all around? Would you rather purchase your own MyDx and test for yourself? Share with your family, friends, and let’s get the conversation growing!